New Product Design & Development

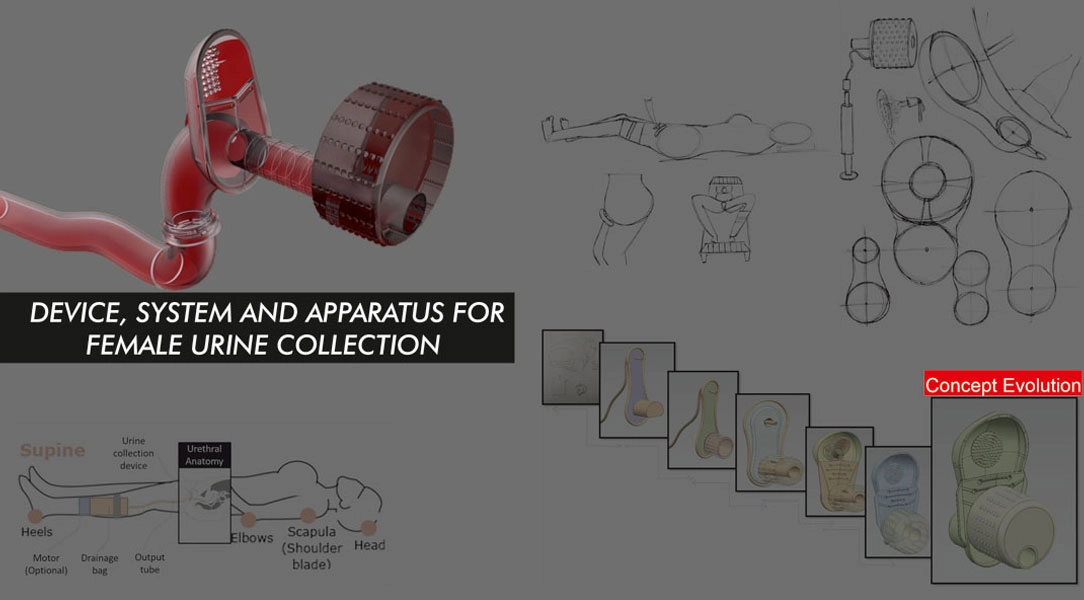

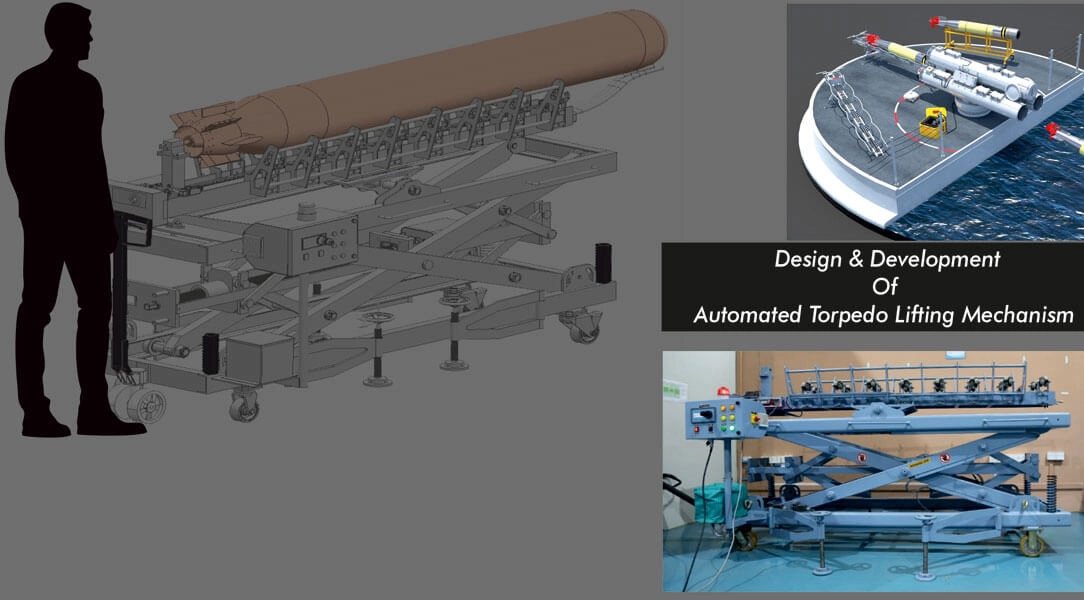

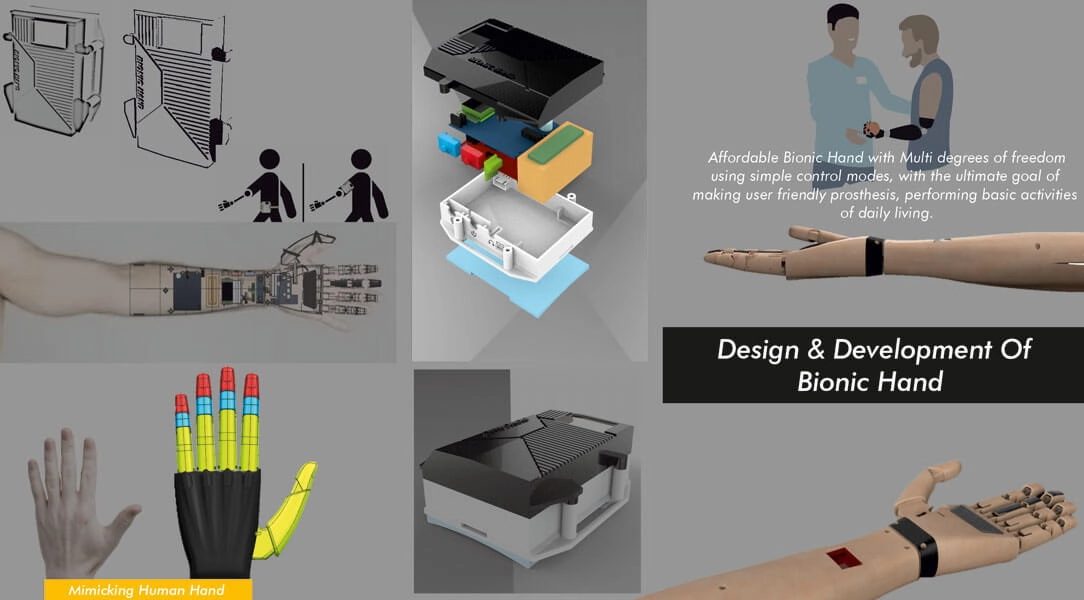

At Techno Centre Engineering(TCE) design starts with understanding the client requirement, Theoretical design based on classical approach, conceptual design, market study, mind mapping, concept finalization, CAD modeling, Proof of concept development and finally manufacturing of real time working prototype.

New product development team works on the project associated with MSME/SME/OEM’s, DRDO, and Public sector units. This product develop involves in interdisciplinary activities in association with Electronic system development team.

Product Design & Development

Product Design team works on Hand sketching, Concept generation, Engineering Design, Interaction with Analysis team, Design optimization, Design for manufacturing & Assembly(DFMA), Manufacturing drawings, 3D CAD Modeling, Prototype manufacturing, Qualification and Complaint tests. Activity of this team includes product for general engineering discipline, Aerospace, Naval, Land combat products and more

Geometric Modeling

Geometric modeling is a part for any engineering design process. This could be bale to convert theoretical design into 3D Computer Aided Design and manufacturing drawings could be generated for further manufacturing process.

Reverse Engineering

Reverse Engineering team works on replication or collection of already available data and apply the engineering on the collected data. There are two type of Reverse engineering,

- Manual Measurement and conversion of data into CAD format for further design, Analysis or Manufacturing

- Reverse Engineering using 3D Scanner like ZEISS COMET: 3D Scanning with Blue LED Fringe Projection. Using 3D Scanner any physical objects could be converted into CAD within short span of time

Manufacturing

Machining, casting, welding, sheet metal work and heat treatment

RUAS consist of our own workshop with porotypes development facility. This centre consist of state of the art machines like CNC Vertical Machining, Slant Bed CNC lathe, CNC Wire EDM Machine and multiple manual lathe and turning beds. Most of the generated design could be converted into Prototype by making using of this manufacturing setup.

Rapid Prototyping

This team work on conversion of design into physical models by making use of Rapid prototyping technique like 3D Printing. We have different type of Rapid Prototyping technologies at RUAS,

- 3D printer with Fuse Deposition Method- DIVIDE BY ZERO-Aion 500 Product

- 3D printer with Multi jet Fusion Technique- HP Jet Fusion 580 Color 3D Printer