Engineering Design & Analysis

World is moving towards tough competition in new product design and development domain especially with low cost and shorter development period.

To achieve this OEM and other general manufacturers undertake lot of engineering design and analysis, using latest computational tools and methods. OEM’s constantly face challenges in executing these analysis due to shortage of man power and resources.

We (TCE) having understood clients requirement, start with theoretical design based on classical approach, then undertake conceptual design, further we carryout market study followed by mind mapping which would be further followed by concept finalization and then CAD modeling is done and Proof of concept is developed. Finally we undertake manufacturing of real time workable prototype.

We (TCE) having understood clients requirement, start with theoretical design based on classical approach, then undertake conceptual design, further we carryout market study followed by mind mapping which would be further followed by concept finalization and then CAD modeling is done and Proof of concept is developed. Finally we undertake manufacturing of real time workable prototype.

TCE’s experienced team specializes in comprehensive engineering analysis using classical Finite element techniques like Linear static, Nonlinear, Impact/Crash, Modal, Harmonic, Shock and Random vibration and it includes both metallic and composite designs, Computational Fluid Dynamics simulations like External aerodynamics, Heat Transfer, Conjugate Heat transfer, Fluid Structure Interaction, Non- Newtonian flow modeling, Free Surface flow modeling, MBD simulations includes Rigid body dynamic simulations, Flexible Body Dynamic Simulations, Electronic System Cooling Analysis, Weight Optimization and Manufacturing Simulation.

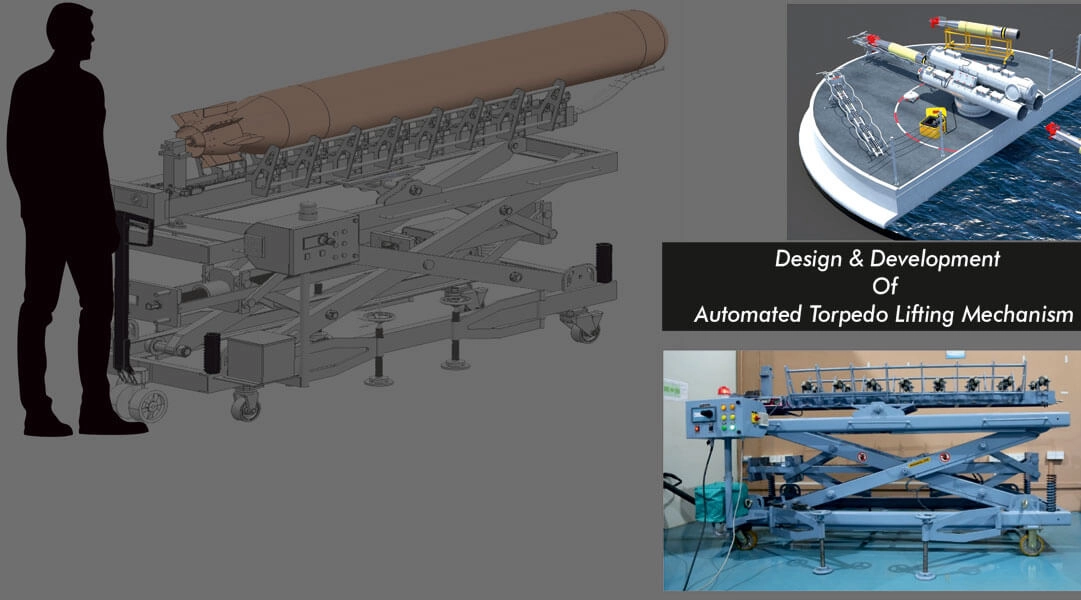

Design and Development

Unified Project team covers multiple disciplines with capability to take up end-to-end design of components, sub-assemblies & systems. This Includes conventional Mechanical system, Automobiles bodies, Powertrains, Engines, Turbomachinery, Gear Box , Aircraft structure design and systems, UAV’s, Bio-Medical devices, Tools, Jigs & Fixtures and Electro Mechanical Systems and Composite structure designs.

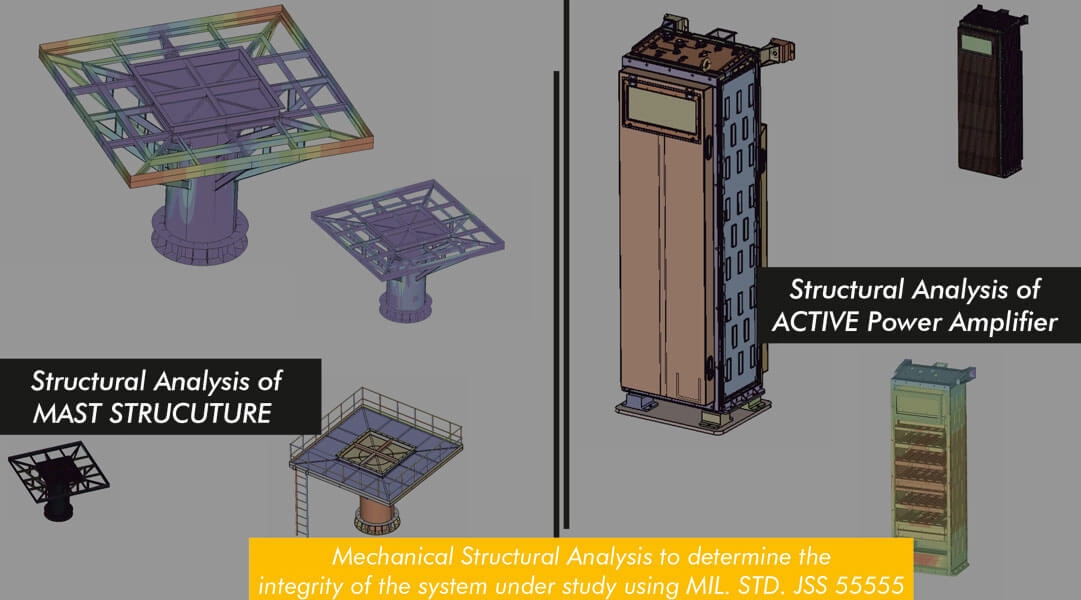

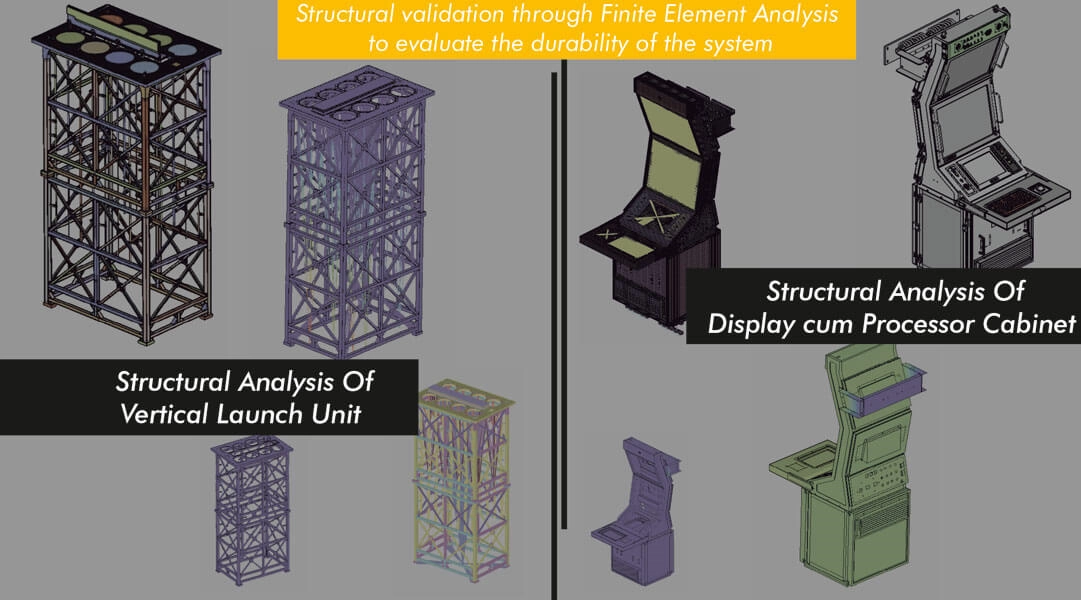

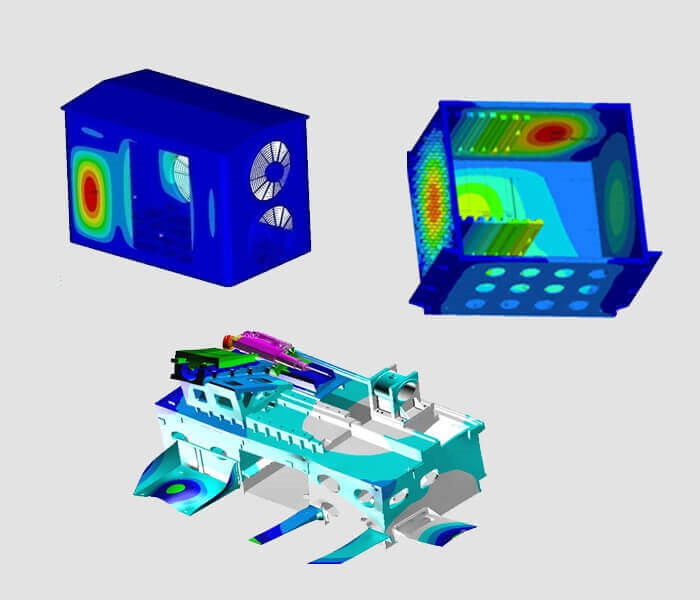

Finite Element Analysis

Techno Centre Engineering has successfully performed many challenging analyses in finite element domain. It includes Linear static, Nonlinear, Impact/Crash, Modal, Harmonic, Shock and Random vibration and it includes both metallic and composite designs. Most of the FE results were validated with experimental at certified laboratories.

Computational Fluid Dynamics

We have very strong CFD team, specializing in Internal aerodynamics, External aerodynamics, Heat Transfer, Conjugate Heat transfer, Fluid Structure Interaction, Non- Newtonian flow modeling, Free Surface flow modeling, Phase change related simulation etc.

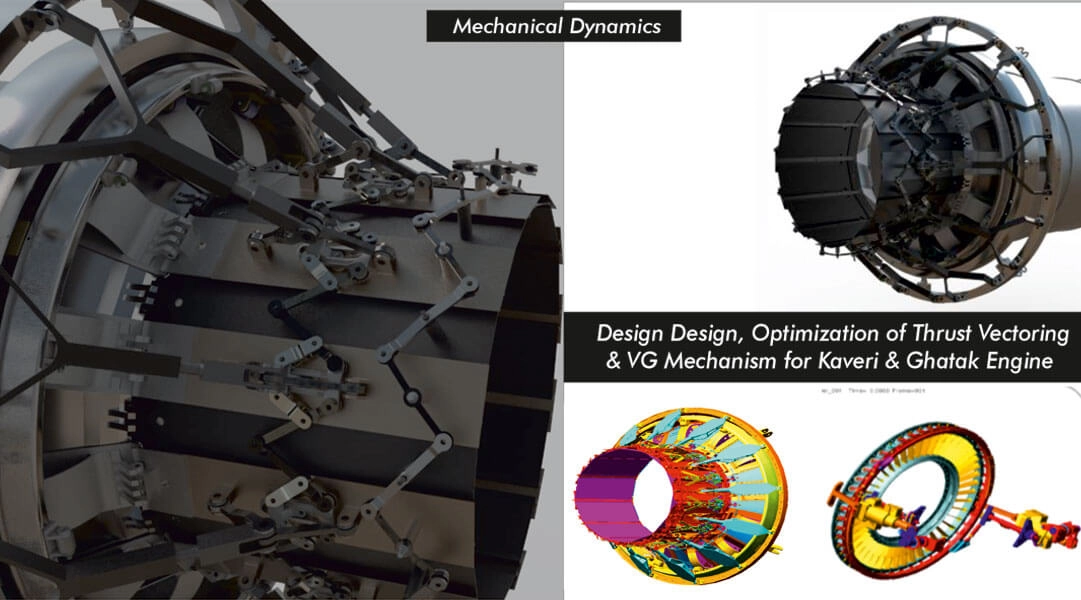

Multi-Body Dynamics

MBD simulations includes Rigid body dynamic simulations, Flexible Body Dynamic Simulations and link sensitivity analysis, Joint Force estimation.

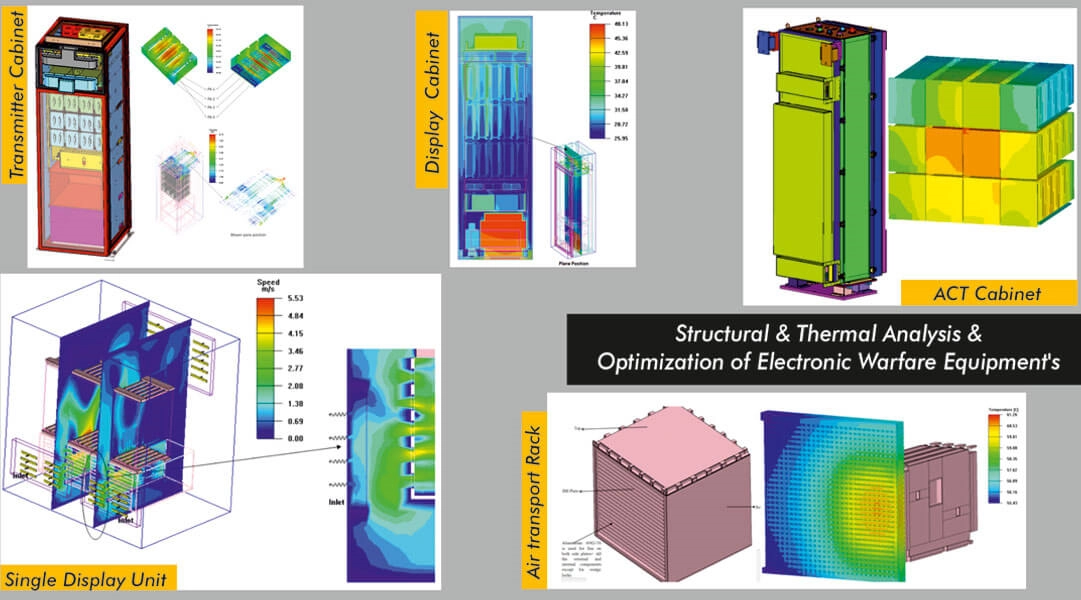

Electronic System Cooling Analysis

Thermal Management is one of the challenging and potential domain in any electronic system design. We have expertise in Natural convection, Forced Convection and Radiation simulations. Complete system could be considered as Conjugate heat transfer with combined structural and fluid medium computations.

Weight Optimization

Weight optimization is very much crucial in aviation and automobile industries. RUAS research team has come up with unique optimization tool, where user could Optimize the system weight without effecting its primary performance.

Vibration and Noise Testing

RUAS consist of state of the art laboratories with very specific non-contact type vibration measurement system i.e. Laser Doppler unit and NI Data Acquisition system to acquire both acceleration and noise data.